879

Arc flash calculations & label making software and mobile apps

Arc Flash Analytic (AFA) software and mobile apps have been developed based on NFPA 70E Standard for Electrical Safety in the Workplace and IEEE 1584 2nd Edition year 2018 Guide for Performing Arc-Flash Hazard Calculations as easy to use and comprehensive instruments for calculating arc incident energy and arc flash boundary, for determining limited, restricted, prohibited approach boundaries and hazard levels required by NEC / CEC and OSHA when work is to be performed on or near the energized equipment.

AFA software program for Windows PCs

Arc Flash Analytic program is now available by mail in disk format or via download from our web server. Payments can be made online using Visa or MasterCard credit card, through PayPal or any other acceptable payment form. The installation package and the individual product registration credentials will be sent to you within 24 hours of placing your order. We offer money-saving bundles of programs. If you bundle Arc Flash Analytic (AFA V6.0) program with ARCAD SCA V1.0 short circuit software you will pay less than purchasing the programs separately.

NOTE: System voltage text box was deactivated and the value was set to 208V AC in unregistered / free version of AFA V6.0

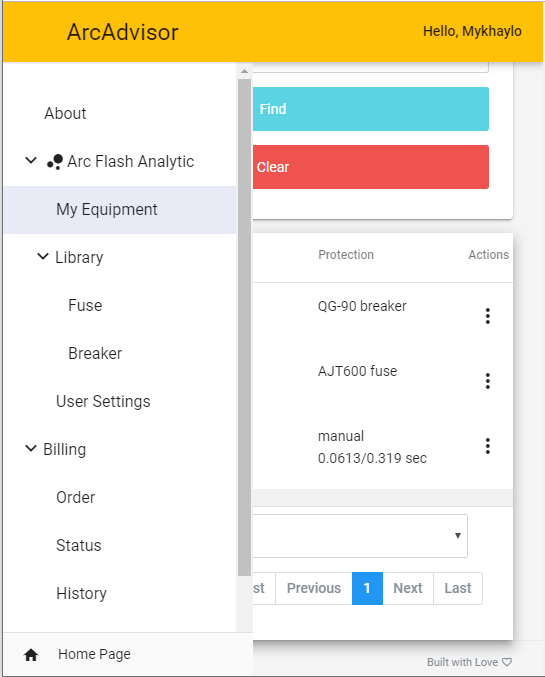

AFA universal web app

AFA Web app is a universal app that can be accessed, operated and shared from anywhere, anytime, on any platform connected to the Internet. Forget about software installation, system compatibility, data loss or virus threat issues. Access to most recent services, updates and the most competitive price in the industry. Work alone or share your access credentials with your team while working on same or multiple projects at a time. Sign-up now and evaluate AFA Web free of charge.

| Sign-Up Free to AFA Web App |

Features and Benefits:

- Detailed arc flash analysis using the IEEE 1584 2nd Edition year 2018 equations and the Lee method.

- Ensure compliance with NEC, OSHA, NFPA 70E, IEEE P1584 and CSA Z462 standards and regulations.

- Instantly determine arcing current, incident energy, arc flash, limited, restricted and prohibited shock approach boundaries, hazard risk category, typical clothing system.

- Perform arc flash boundary calculations based on 1.2 cal/cm^2 (5 Joules/cm^2) onset energy to second degree burn for bare skin exposure per IEEE 1584 Guide and other incident energy levels as well, such as the rating of proposed personal protective equipment, or evaluated onset to second degree burn energy.

- Calculate initial arc blast explosion pressure and arc flash TNT (Tri-Nitro-Toluen) mass equivalent

- Add fuse and circuit breaker data including time-current characteristics for the devices that are not already featured in the built-in protection device library.

- Set arc duration cut-off in the 2 to 10 second range.

- Create warning labels in English and a variety of international languages.*

- Preview, save, print arc flash labels in high resolution graphic and PDF formats.*

- Save input configuration, protection device information.

- Perform analysis using metric, imperial units.

- Save reports including equipment data, calculation results, warning label.

Arc-Flash-Analytic V6.0 How To's

IEEE 1584 2nd Edition Empirical Model Equations

Development of this model is discussed in 1584 IEEE Guide for Performing Arc-Flash Hazard Calculations 2nd Edition. The empirically derived model, based upon statistical analysis and curve fitting programs, is applicable for systems with:

- Voltages in the range of 208 V to 15 000 V, three-phase (line-to-line).

- Frequencies of 50 Hz or 60 Hz.

- Bolted fault current (rms symmetrical):

- 208 V - 600 V : 500 A to 106 000 A

- 601 V - 15 000 V : 200 A to 65 000 A

- Gaps between conductors:

- 208 V - 600 V : 6.35 mm (0.25 in) to 76.2 mm (3 in.)

- 601 V - 15 000 V : 19.05 mm (0.75 in) to 254 mm (10 in.)

- Working distances of 305 mm (12 in) or larger

- Fault clearing time: no limit

- Enclosure dimension limits:

- Maximum Height or Width: 1244.6 mm (49 in.)

- Maximum Opening Area: 1.549 m2 (2401 in2)

- Minimum Width: The width of the enclosure should be larger than four times the gap between conductors (electrodes).

- Electrode Configurations:

- VCB: Vertical conductors/electrodes inside a metal box/enclosure

- VCBB: vertical conductors/electrodes terminated in an insulating barrier inside a metal box/enclosure

- HCB: horizontal conductors/electrodes inside a metal box/enclosure

- VOA: vertical conductors/electrodes in open air

- HOA: horizontal conductors/electrodes in open air

IEEE 1584 Lee Equations

There are alternative calculation methods for system parameters which fall outside the range of the model. For cases with vertical electrodes in open air (VOA electrode configuration) where voltage is over 15 kV or gap between conductors is more than 254 mm (10 inches), the theoretically derived Lee method can be applied and it is implemented in Arc Flash Analytic version 6.0. The Lee method based upon Lee’s paper, is applicable for three-phase systems in open air substations, and open air transmission and distribution systems. This model is intended for applications where faults will escalate to three-phase faults. Where this is not possible or likely, this model will give a conservative result.

Arcing Current Variation Correction Factor

The first addendum for the 2002 edition of IEEE 1584 was published in 2004. Known simply as IEEE 1584a, this addendum added an 85% factor for reducing the calculated arcing short circuit current for systems up to 1kV. The reduction was to account for variations that may occur in the actual arcing current which could affect how fast a protective device may operate. If the reduced arcing current resulted in a longer clearing time and larger incident energy, results based on the adjusted current would be used. Instead of a fixed 85% factor, the IEEE 1584 2nd edition includes an “Arcing Current Variation Correction Factor” based on using a new equation. This represents a more accurate arcing current variation based on the electrode configuration as well as other factors and applies for all voltages.

The AFA v6.0 arc flash software program enables calculations for both of the above considered cases. The program takes equipment and electrode configuration, gap between electrodes, enclosure size, short circuit fault current value and system voltage on input, and determines both the expected arc current and the reduced arcing fault currents at potential point of fault. Next, arc duration is determined based on the amount of predicted arcing current and selected upstream protection device type and rating.

Then, the incident energy, arc flash boundary, shock protection boundaries and level of personnel protective equipment are determined both at the expected arc current and the reduced arcing fault currents and associated arc duration. The larger incident energy is taken as the model result. This solution was developed by comparing the results of arc current calculations using the best available arc current equation with actual measured arc current in the test database. Note how the System Summary and Calculation Results Screen displays calculation results both for predicted and reduced arcing current with worst case scenario values highlighted. These are the values that will be displayed on warning label once you click on [Create Label] button.

Enclosure Size Correction Factor

The enclosure size can have a significant impact on the arc flash energy being expelled and reaching a worker. To address this, additional enclosure sizes were included in the IEEE 1584 - 2018 test program. An enclosure size correction factor has also been introduced to adjust the incident energy for smaller and larger enclosures. For equipment operating at voltages less than 1000 volts, the IEEE 1584 2nd edition now makes a distinction between "Shallow" enclosures which are less than eight (8) inches in depth and "Typical" enclosures that are greater than 8 inches in depth.

Single-phase systems

IEEE 1584 empirical model does not cover single-phase systems. Arc-flash incident energy testing for single-phase systems has not been researched with enough detail to determine a method for estimating the incident energy. Single-phase systems can be analyzed by using the single-phase bolted fault current to determine the single-phase arcing current. The voltage of the single-phase system, (i.e. line-to-line, line-to-ground, center tap voltage, etc.), can be used to determine the arcing current. The arcing current can then be used to find the protective device opening time and incident energy by using the three-phase equations provided in IEEE 1584 2nd edition and implemented in Arc Flash Analytic v6.0 software program. The incident energy result is expected to be conservative.

AFA V6.0 for Windows operated PCs - System Requirements & Troubleshooting

AFA V6.0 was written in C# programming language, best viewed as a descendant of both C++ and Java languages. The language was developed by Microsoft within its .NET initiative and later approved as a standard by ECMA (ECMA-334) and ISO (ISO/IEC 23270:2006). AFA V6.0 requires Microsoft .NET Framework Version 3.5 or higher to run. If you experience problems running AFA V6.0 once you install it on your PC, check please if you have .NET Framework Version 3.5 or higher installed on your PC system. To see which versions are installed, view the %WINDIR%\Microsoft.NET\Framework directory. (You should also view the Framework 64 directory on a 64-bit computer, which can have 32 or 64-bit versions installed.) Each version of the .NET Framework has a directory, and the first two digits of the directory name identify the .NET Framework version; for example: v1.1.4322 for the .NET Framework 1.1, v3.5 for the .NET Framework 3.5, and so on.

If there is no Microsoft .NET framework installed on your system, or the installed .NET framework version is less than 3.5, please follow the Download .NET Framework Version 3.5 link to update your system. Should you encounter any problem installing or running AFA V6.0, contact us and we will assist you in identifying and resolving the problem.

Copyright © 2019 ARCAD INC. All rights reserved.